Humidification Water Pre-Treatment Systems

Controlling Water Quality Issues

Specific to Fan-Assisted High Pressure Humidification Systems

THE WATER SUPPLY TO THE HIGH PRESSURE PUMP REQUIRES TWO FORMS OF WATER TREATMENT:

A. Filtration of Suspended Solids – accomplished by the inclusion of the 5 micron cartridge type filter located on the incoming water supply line to the pump – addresses suspended solids which can disrupt the flow and quality of pump pressurization, optimum pump valve functionality and optimum nozzle atomization. Additionally, each nozzle has an inserted 5 micron filter. Five micron filtration is standard in both pre-pump low pressure and post pump high pressure supply lines – a single hair is about 100 microns in diameter.

B. Filtration of Dissolved Solids – addressing the presence of solids in a dissolved state understood as “in solution” which divide into two general categories: “dissolved calcium” and “total dissolved solids” (TDS).

• Dissolved Calcium forms scale over time within the pump system, the nozzle body and surface of the nozzle cap. Calcium scale is solved by two forms of water treatment:

1. Water Softening – exchanges calcium ions (scale producing) with sodium ions (harmless) through the use of salt and is the answer to scale for woodworking and textile applications.

2. Template Induced Crystallization – an alternative to softening – chemical free scale prevention rendering calcium ions as inactive and harmless microscopic crystals. ScaleX2 is an example of this type. And again, a clear solution for woodworking and textiles.

• Total Dissolved Solids (TDS) are an issue primarily in applications where air quality is a major issue such as printing, labels, or electronics environments. The main issue is the total of all dissolved solids plate out – turning from a dissolved state to solids in the air when atomized moisture evaporates – forming fine white powder dust known as air dusting. Two water treatment systems are utilized: Reverse Osmosis Systems (RO) and Deionized Blending Systems (DIBS).

1. Reverse Osmosis (RO) is a membrane filtration which removes all total dissolved solids down to 96% purity. A very safe approach to the solution of calcium and all dissolved solids.

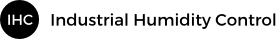

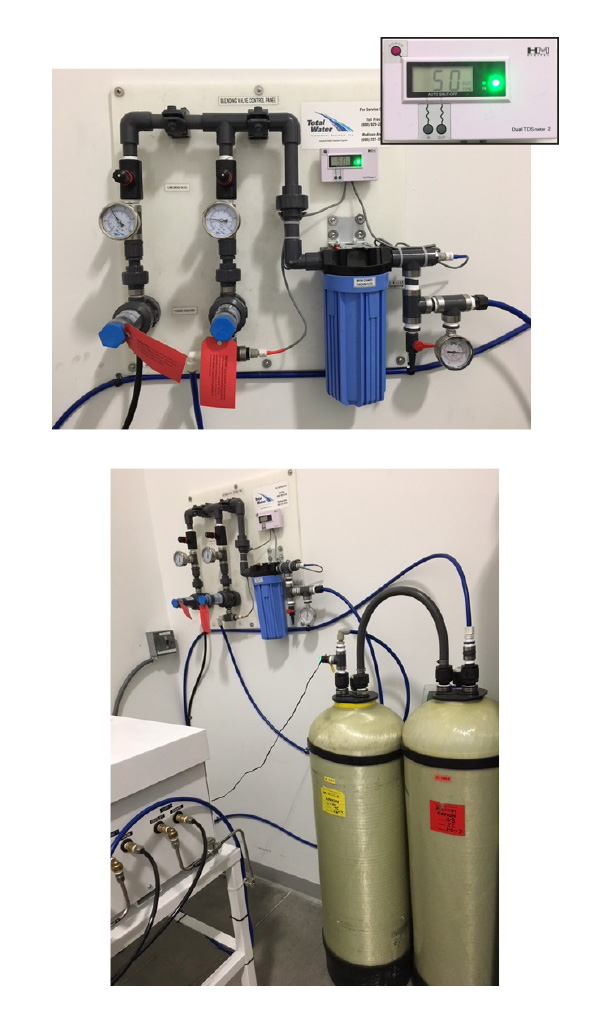

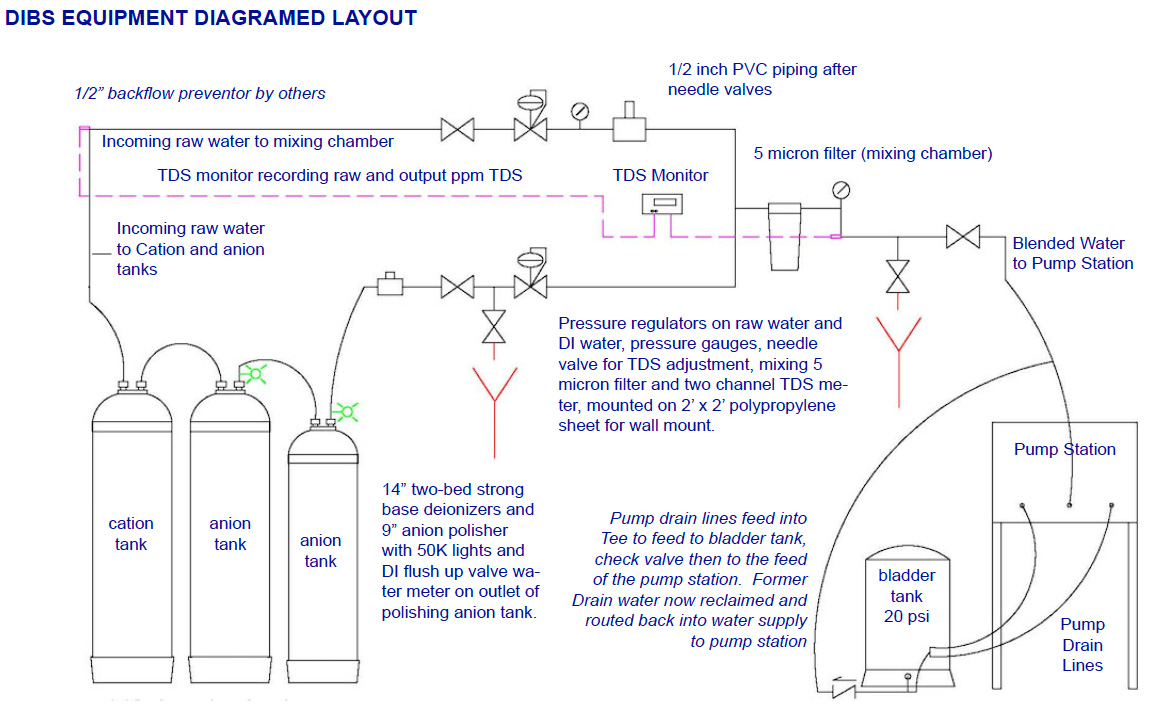

2. Deionized Blending System (DIBS) uses deionized water and blends back untreated water to a desired parts per million (ppm) of solids generally set at 20-50 ppm tds. An inexpensive alternative to RO and addresses the fundamental issues of calcium and tds.

We provide guidance in all of our projects as to the recommended approach for addressing the total need in all applications. It is always best to consult with local water treatment experts such as Total-Water based in Madison WI with support capability over the midwest and eastern US region.