Industrial Humidity Control (IHC) supplies all parts for our humdity control systems manufactured in the last 14 years.

To best prepare for ordering parts, check and record the serial number on the outside of the pump enclosure as that is the master specification of all parts in your pump station.

As of 2018 we have discontinued post pump Hylok 100 micron “T” filters. Instead, 5 micron filters are now standard for all nozzles used in our systems as the primary post pump filtration function. We continue to supply all Hylok parts.

Upon receipt of your purchase order, we generally ship same day or next day ground unless otherwise specified.

We are thankful for your continuing business with us.

Part

Part Number

Description / Information

Specifications / Guidelines

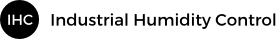

• IHC-TX1812S1

• IHC-TX1508S34

Bare Pump Replacement up to 1 gpm

Bare Pump Replacement from 1.1 gpm up to 3.8 gpm

TX series General High Pressure Pumps are triplex plunger – solid shaft – pulley driven which allows easy capacity output modifications with pulley and belt changes.

• IHC-RK123

• IHC-RK159

• IHC-RK167

General Pump Valve Repair Kit #123

General Pump Plunger Repair Kit #159

General Pump Seal & Packing Repair Kit #167

IHC includes 1 each Kit #123 & #159 and 3 each #167 (for three valves) in your spare parts package included in your original pump station order. For re-ordering, you will need three of the #167 repair kits. All kits are for 18 mm pumps.

• IHC-HRO20

Neptronic Humidistat Controller (with sensor)

Wall/column mount type. Requires 3 wire 18 gauge cable for: Terminal 1. Common; Terminal 2. 24Vac Input; and Terminal 8. 24Vac Output. Available with remote sensor (Part #IHC-S10).

• IHC-T38-500

• IHC-T38-100

• IHC-T38-50

500′ Roll 3/8″ High Pressure Nylon Tube

100′ Roll 3/8″ High Pressure Nylon Tube

50′ Roll 3/8″ High Pressure Nylon Tube

Installer friendly high pressure tube rated for 3550 burst pressure for 1000 psi water supply from pump station to zone nozzles. Uses Slip-Lok fittings to complete all supply line runs.

• IHC-WC38

3/8″ Steel “Vinyl Coated” Wall Clamp – Black –Clamps are ordered packaged in quantities of ten – available in 1/2″ (Part #IHC-WC12)

Screw type clamps are used to install high pressure tube to flat surfaces – use every 10′. Note: most tube runs are in ceiling and zip ties are most commonly used every 10′.

• IHC-SL38T

• IHC-SL38C

• IHC-SL38E

3/8″ Slip-Lok Fitting – Three Way Tee

3/8″ Slip-Lok Fitting – Coupling/Union

3/8″ Slip-Lok Fitting – 90˚ Elbow

Stainless steel Slip-Lok fittings are used for completing all high pressure 3/8″ supply lines from the pump station to all nozzle locations in a zone.

• IHC-MR-15-6

• IHC-MR-18-8

• IHC-MR-24-12

• IHC-MR-2415-18

15″ Diameter Mist Ring with 6 nozzle ports

18″ Diameter Mist Ring with 8 nozzle ports

24″ Diameter Mist Ring with 12 nozzle ports

24″ & 15″ Diameter Double Mist Ring with 18 nozzle ports

Mist Rings are mounted to the face of fans with zip ties. All mist rings include a ball valve and Slip-Lok assembly which receives the high pressure water supply line from the pump station.

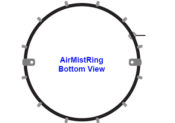

• IHC-30AMR

30″ Diameter 3/8″ Stainless Steel AirMistRing

AirMistRings are ceiling hung – requires minimum 15′ ceiling with sufficient unobstructed air spaces for complete evaporation. Standard with 12 nozzle ports – 10/24 NPT – with swivel nozzle adaptors to direct moisture plumes up to 90˚ in any direction. New product added in 2018 as an alternative to using fans.

• IHC-2.65

Stainless Steel High Pressure “Ruby Orifice” Insert Nozzle

Black Band

Output Capacity: 2.65 lbs/hr

0.085 mm / .0033” orifice .0053 gpm / 2.65 lbs/hr

Nozzle Tested with Filter @ 1000 psi Operating Pressure:

20 cc/minute flow rate @ 1000 psi = 0.0053 gpm x’s 500.72 lbs/hr = 2.65 lbs/hr

Internal spring set for open and closing at 350 psi – Special order 10/24 & 12/24 thread.

• IHC-3.97

Stainless Steel High Pressure “Ruby Orifice” Insert Nozzle

White Band

Output Capacity: 3.97 lbs/hr

0.1 mm / .004” orifice .0079 gpm / 3.97 lbs/hr

Nozzle Tested with Filter @ 1000 psi Operating Pressure:

30 cc/minute flow rate @ 1000 psi = 0.0079 gpm x’s 500.72 lbs/hr = 3.97 lbs/hr

Internal spring set for open and closing at 350 psi – stocked standard 10/24 – 12/24 special order.

• IHC-5.29

Stainless Steel High Pressure “Ruby Orifice” Insert Nozzle

Red Band

Output Capacity: 5.29 lbs/hr

0.15 mm / .006” orifice .01 gpm / 5.29 lbs/hr

Nozzle Tested with Filter @ 1000 psi Operating Pressure:

40 cc/minute flow rate @ 1000 psi = 0.01057 gpm x’s 500.72 lbs/hr = 5.29 lbs/hr

Internal spring set for open and closing at 350 psi – stocked standard 10/24 – 12/24 special order.

• IHC-7.94

Stainless Steel High Pressure “Ruby Orifice” Insert Nozzle

Blue Band

Output Capacity: 7.94 lbs/hr

0.2 mm / .008” orifice .016 gpm / 7.94 lbs/hr

Nozzle Tested with Filter @ 1000 psi Operating Pressure:

60 cc/minute flow rate @ 1000 psi = 0.01585 gpm x’s 500.72 lbs/hr = 7.94 lbs/hr

Internal spring set for open and closing at 350 psi – stocked standard 10/24 – 12/24 special order.

• IHC-10.58

Stainless Steel High Pressure “Ruby Orifice” Insert Nozzle

“Colorless” Band

Output Capacity: 10.58 lbs/hr

0.3 mm / .012” orifice .021 gpm / 10.58 lbs/hr

Nozzle Tested with Filter @ 1000 psi Operating Pressure:

80 cc/minute flow rate @ 1000 psi = 0.021 gpm x’s 500.72 lbs/hr = 10.58 lbs/hr

Internal spring set for open and closing at 350 psi – Special order 10/24 & 12/24 thread.

• IHC-NPL

Nozzle Plug – 10/24 NPT – nickle plated

Nozzle Plugs are ordered in paks of ten each. Plugs are used to close off a nozzle port.

• IHC-NF5

5 Micron Nozzle Filter

Nozzle filters are now standard with all nozzles as of 2018 and are ordered in paks of 100 each. Nozzles sold prior to 2018 can be upgraded to now include this filter. Filters insert in the threaded end of the nozzle.

• IHC-NSA

Nozzle Swivel Adaptor – 10/24 NPT

Nickel plated with 10/24 male & female ends – attains up to 30˚ angle adjustment for directional pointing of plume – shown as joining three swivels to point nozzle plume in 90˚ angle – newly added to be used with AirMistRing.

• IHC-PFH10

• IHC-PFC-5

• IHC-PFC-1

10″ Pre-Filter Housing with 9 & 3/4″ Cartridge

Pre-Filter Cartridge (9 & 3/4″ x 5 Micron)

Pre-Filter Cartridge (9 & 3/4″ x 1 Micron)

Supply water pre-filter located on the low pressure water supply side to the pump. Depending upon type of water pre-treatment system, this function may or may not be included as standard on the pump station.

• IHC-HTF100

• IHC-HTF-RK

• IHC-HTF-E

Hylok Tee Filter with 100 Micron Filter

Tee Filter Repair Kit

Tee Filter Element

Hylok stainless steel 100 micron post-filters are used to filter small fines which may be generated from pump operation and affect nozzle performance. As of 2018, we have discontinued this function and replaced with 5 micron nozzle filters now standard in all nozzles.

• IHC-SX2-11

• IHC-SCLX2-1

• IHC-SX2-12

• IHC-SCLX2-2

• IHC-SX2-12B

• IHC-SCLX2-4

1 GPM w/ 10″ Cartridge

> 10″ Replacement Cartridge

2 GPM w/ 20″ Cartridge

> 20″ Replacement Cartridge

4 GPM w/ 20″ x 4 & 1/2″ Cartridge

> 20″ x 4 & 1/2″ Replacement Cartridge

ScaleX2 Water Treatment an economical alternative for water softening and functions as a scale inhibitor to protect against calcium scale buildup. The ScaleX2 specifications and information pdf document can be downladed from the Water Treatment page.

• IHC-PO16

Oil for all “General Pump” type high pressure pumps

16 oz – minimum order quantity of two each.

Contact IHC For All Parts Pricing – See Contact Page for email or phone contact information